Forged: The Metallurgical Resilience and Relevance of the Western Balkans

Western Balkans' rich metallurgical legacy from ancient civilization to global supply hub for high-quality, cost-competitive metal components.

The Western Balkans have long been a crucible of culture, craftsmanship, and commerce—and at the heart of this legacy lies metallurgy. From ancient furnaces nestled in the mountainous interiors to modern fabrication plants exporting precision parts to global markets, the story of metal in this region is one of resilience, reinvention, and growing international relevance.

Ancient Roots in Metallurgical Innovation:

Long before modern borders took shape, the Western Balkans—encompassing present-day Bosnia and Herzegovina, Serbia, Montenegro, and neighboring regions—were home to some of the earliest known metalworking cultures in Europe. Archaeological evidence from the Vinča and Vučedol cultures reveals sophisticated use of copper and bronze as early as the 5th millennium BCE. These communities not only mined and smelted ore locally but also traded metal goods across Europe, laying the groundwork for a thriving regional industry.

During the Iron Age, the Illyrians and later the Roman Empire leveraged the area's rich ore deposits and skilled labor to produce tools, weapons, and infrastructure materials. Metallurgy in the region became a strategic economic and military pillar.

Ottoman Adaptation and Influence:

Under Ottoman rule from the 15th century onward, metallurgy in the Western Balkans adapted and evolved. Local craftsmanship was integrated into the empire’s supply chains, with foundries in Sarajevo, Novi Pazar, and Skopje producing tools, weaponry, and artisanal goods for both military and civic use.

Metalwork in this period fused Ottoman aesthetics with Balkan engineering, giving rise to products like filigree jewelry, copper cookware, and engraved arms—prized not just regionally, but throughout the empire’s vast trade network.

Soviet Industrialization:

In the post-WWII period under the Soviet Union, the Western Balkans, known as Yugoslavia, industrialized the metallurgical sector on an unprecedented scale. State-owned enterprises built large smelters and fabrication facilities in cities like Zenica, Smederevo, and Nikšić, churning out steel, aluminum, and alloys to serve both domestic needs and international partners.

Being outside the Warsaw Pact, Yugoslavia’s non-aligned position enabled it to trade with both Eastern and Western European blocs, embedding a dual-capability system—producing in bulk for the East while meeting high-quality standards for the West.

Modern Renewal in Precision, Efficiency, and Reach:

After the economic and political upheavals of the 1990s, the metallurgy industry in the Western Balkans began to modernize. Through EU integration efforts, foreign direct investment, and local reform, the region transformed from legacy industry to lean, globally competitive production.

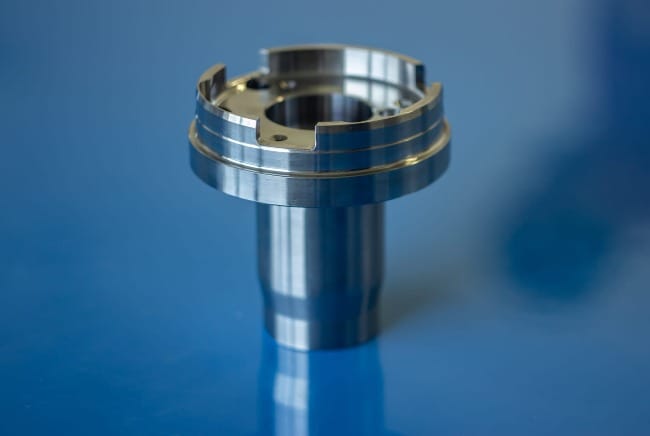

Today, countries like Bosnia and Herzegovina and Serbia are core suppliers to Western Europe’s automotive and transportation industries, delivering high-spec components for giants like Volkswagen, Mercedes-Benz, and Siemens. Metal fabricators across the region specialize in everything from CNC machining and laser cutting to full-system assembly and corrosion-resistant coatings.

Crucially, this transformation is not limited to trade in only in Europe.

Forging Global Expansion:

As global supply chains shift and diversify, the Western Balkans are becoming a strategic metallurgy partner not only for Europe, but also for emerging and established markets in North Africa and North America.

- North Africa: Trade agreements and geographical proximity have enabled Balkan manufacturers to supply construction-grade metals, machinery components, and transportation systems to countries like Egypt, Algeria, and Morocco. With large infrastructure and energy projects underway in these regions, demand for reliable metal products is surging—and Balkan suppliers are stepping in to fill that gap.

- North America: Thanks to rising interest in forging resilient global partnerships to secure high quality metals and reliable supply chains, firms in the Balkans are building strategic relationships with a cross section of companies in the United States, Mexico and Canada, particularly in sectors like automotive, heavy machinery, construction and energy. North American OEMs value the region’s combination of EU-compliant high quality standards, competitive costs, and consistent delivery capabilities.

Strategically located between Europe, Asia, and the Mediterranean basin, the Western Balkans serve as a natural hub for triangulated trade. Today, many metal manufacturers are now building dedicated supply chains that link EU operations with distribution points in Casablanca, Houston, and Montreal.

Refined by the Past, Engineered for What’s Next:

From ancient bronze tools to aerospace-grade components, the metallurgical journey of the Western Balkans is one of continuous adaptation and growth. Today, the region is not just recovering its legacy—it’s redefining it on a global stage.

As global transportation systems and cities continue to electrify and modernize, and Western manufacturers seek dependable partners, the Balkans offer a rare combination of quality, flexibility, and strategic access. Whether for a German train manufacturer, a Canadian EV startup, or a Moroccan infrastructure consortium, the Western Balkans have proven one thing: their metal is forged to meet the future.

Looking for high-quality, reliable, and cost-competitive metal component companies for supply chain needs?

Contact Texas Global Business today to get connected with vetted, export-ready fabrication and metalworking firms from the Western Balkans. We help manufacturers operating in North America find trusted manufacturing partners that meet the highest standards in quality, compliance, and delivery performance.

📩 Reach out now at info@texasglobal.biz and let us help you strengthen your supply chain with world-class metal goods from a region built on metallurgical excellence.